-

SLS300 Series — Standard Tote-handling Shuttle Robot Automated storage & retrieval system

The SLS300 shuttle robot ASRS is an efficient buffering solution for totes and cartons, with fixed width load handling device to handle standard size products.

It is also the ideal solution for fully automated crates and cartons with efficient throughput, flexible specification options, better use of space, and more reliable operating equipment.

Advantages:

· High storage density: Effective dual storing location design with dense storage spaces

· Large order handling capacity: Multiple shuttles jointly process the storage units in parallel

· High device utilization: Achieve high-speed loading and unloading and increase the picking efficiency

· Flexible layout: Adjust the layout flexibly according to customer’s needs

· Convenient scalability: Deploy required numbers of shuttles according to the efficiency needs of customers during different periods

· Low power consumption: Adopt energy-efficient parts and energy saving drive solutions to conserve energy and reduce consumption

- Applicable Scene

-

The SLS300 shuttle robot system can be used in E-commerce, Media, Tobacco, Pharmaceutical, Electricity, Electronics, and other industries.

Driving

Speed: 4m/s

Acceleration: 2m/s²

Load

Standard: 35KG(Max50KG)

Cargo Size: Length*Width

(MAX)600*400

Overall Performance

Compound throughput efficiency of single aisle≥2500boxes/hour

-

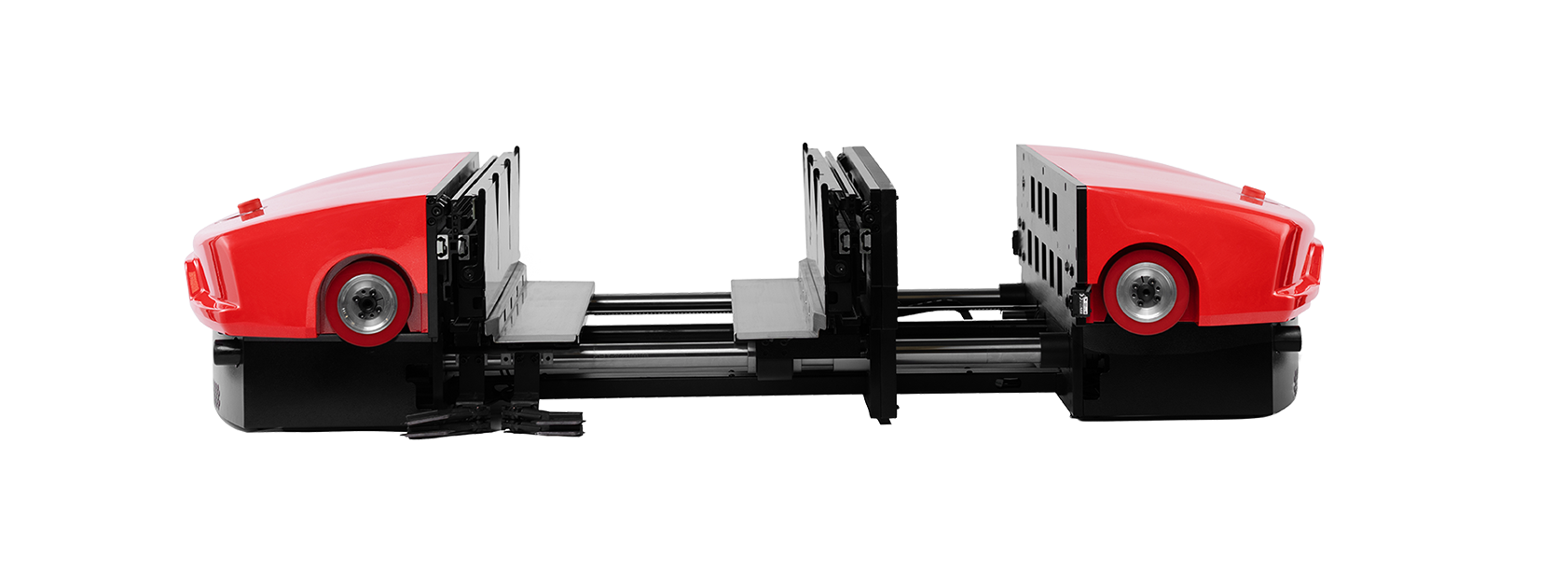

SLS400 Series — Variable Tote-handling Shuttle Robot ASRS

SLS400 is a variable tote-handling shuttle robot ASRS for mixed storage that provides excellent storage density and high rack space utilization, with adjustable width load handling device to handle different product sizes.

Advantages:

· High storage density: Effective hybrid storage location design with dense storage spaces

· High flexibility of system operation: The size of the goods location can be dynamically adjusted as needed

· Broad goods size compatibility: Handle most of the loading of source boxes (length and width size of 200-850mm)

· Investment amount reduction: Flexible barcode recognition and size confirmation system

· Large order handling capacity: Multiple shuttles jointly process the storage units in parallel

· High device utilization: Achieve high-speed loading and unloading and increase the picking efficiency

· Flexible layout: Adjust the layout flexibly according to customer’s needs

· Convenient scalability: Deploy required numbers of shuttles according to the efficiency needs of customers during different periods

· Low power consumption: Adopt energy-efficient parts and energy saving drive solutions to conserve energy and reduce consumption

- Applicable Scene

-

The SLS400 shuttle system can be used in e-commerce, media, tobacco, medicine, electricity, electronics, aviation, and other industries.

Driving

Speed: 4m/s

Acceleratio: 2m/s²

Load

Standard: 35KG(Max50KG)

Cargo Size: Length*Width*Height

200~850mm*200~650mm*60~500mm

Overall Performance

Compound throughput efficiency of single aisle≥1000boxes/hour

-

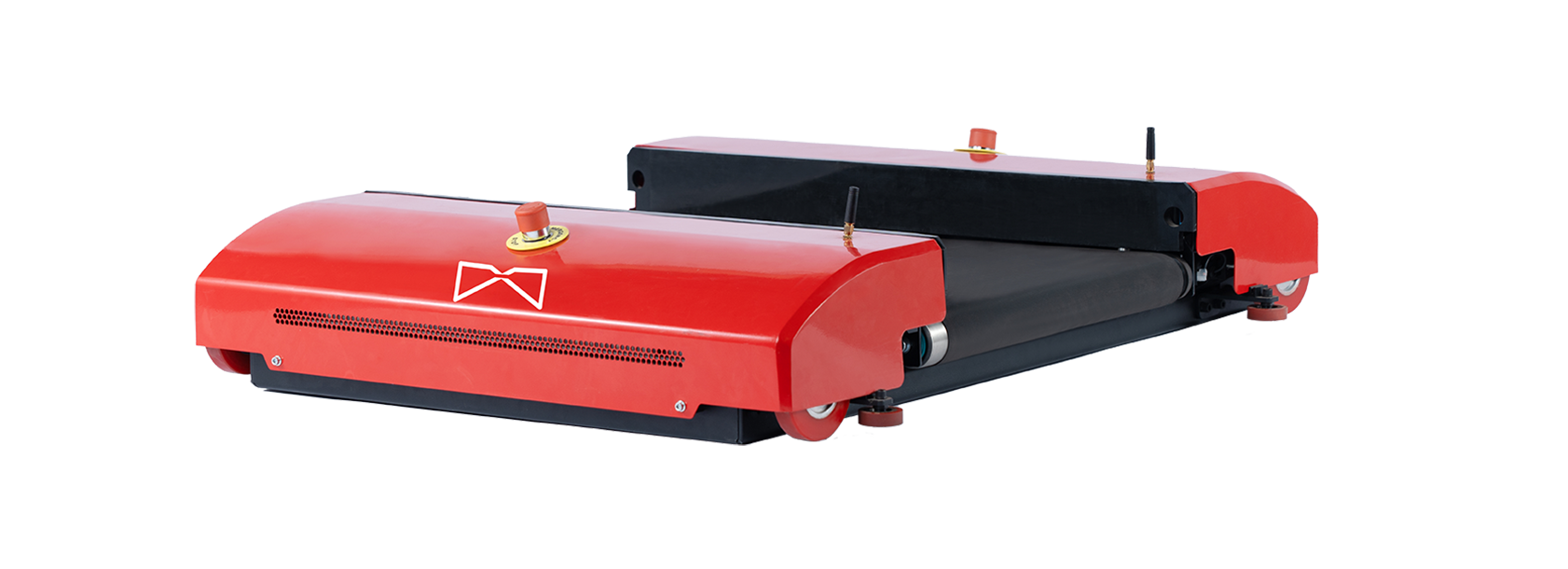

SLS500 Series — Buffering And Sorting Shuttle Robot ASRS-SLS500

SLS500 is a shuttle robot system for buffering and sorting based on flow racking and supports warehouses with high throughput, multiple aisles, and large storage depths.

The system also provides a first-in-first-out mechanism, and enables fast automatic replenishment and high storage and retrieval efficiencies.

It is suitable for short-term storage and sorting large numbers of goods.

Advantages:

· High storage density: Effective hybrid storage location design with dense storage spaces

· Multiple runners and large and deep locations: Buffer a large quantity of goods to effectively buffer the peak and off-peak of replenishments

· First-in-first-out, automatic quick replenishment

· Broad goods size compatibility: Handle most of the inbound buffering of source boxes (length and width size of 200-600mm)

· Investment amount reduction: Flexible barcode recognition and size confirmation system

· Large order handling capacity: Multiple shuttles jointly process the storage units in parallel

· High device utilization: Achieve high-speed loading and unloading and increase the picking efficiency

· Flexible layout: Adjust the layout flexibly according to customer’s needs

· Low power consumption: Adopt energy-efficient parts and energy saving drive solutions to conserve energy and reduce consumption

· The high storage and retrieval efficiency is suitable for short-term storage and picking of a large quantity of goods

- Applicable Scene

-

The SLS500 shuttle system can be widely used in the manufacturing industry, business applications, distribution centers, assembly workshops, and warehouses with a high dispatch frequency.

Driving

Speed: 4m/s

Acceleration: 2m/s²

Load

Standard: 3KG(Max20KG)

Cargo Size: Length*Width*Height

200~600mm*200~400mm*150~500mm

Overall Performance

single inbound efficiency of single aisle≥540boxes/hour

-

SLS600 Series — 3D Shuttle Robot ASRS -SLS600

The SLS600 3D shuttle robot ASRS enables flexible shuttle movements between aisles and system capacity adaptation by adjusting the number of shuttle robots.

Advantages:

· Fast and Flexible Operation: The shuttle devices in the 3D system can move horizontally, vertically, and even diagonally, enabling them to access any location within the racking structure quickly and efficiently.

· Accurate Inventory Management: The four-directional AS/RS shuttle robot Automated storage & retrieval system(ASRS) is integrated with warehouse management systems (WMS) or inventory control software, enabling real-time tracking and management of inventory.

· Scalability and Adaptability: The modular design of the four-directional shuttle robot system makes it highly scalable and adaptable to changing business needs.

- Applicable Scene

-

The SLS600 shuttle system is applicable in low-throughput and high-efficiency use cases such as parts warehouses and books as well as high-throughput and high-efficiency use cases such as e-commerce.

Driving

Maximum speed of longitudinal travel ≥4m/s

Maximum speed of lateral travel ≥2m/s

Load

Standard: 35KG(Max50KG)

Cargo Size: Length*Width*Height

200~850mm*200~650mm*160~500mm

Overall Performance

Compound throughput efficiency of single aisle:100~1000 boxes/hour

+49-160-94400866