-

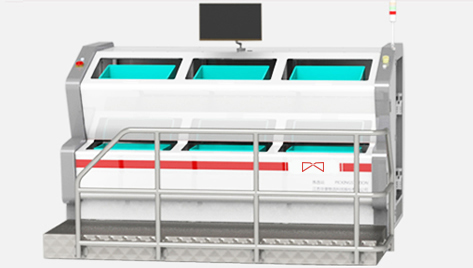

PSD310 Double-Layer Sorting Station

The PSD310 series is an important part of the “goods-to-person” system, which is used for split picking together with the AS/RS system and the conveyor system.

- Applicable Scene

-

The PSD310 double-layer sorting station can meet the split-picking needs of multiple varieties and small orders. This type of warehouse workstation suits various fields, including food, tobacco, medicine, cosmetics, publications, electronic manufacturing, auto parts, e-commerce, new retail, omnichannel logistics, etc. PSD310 can be used for sorting and as a general workstation for receiving goods, counting inventory, auditing, and other tasks.

Driving

Load

Overall Performance

-

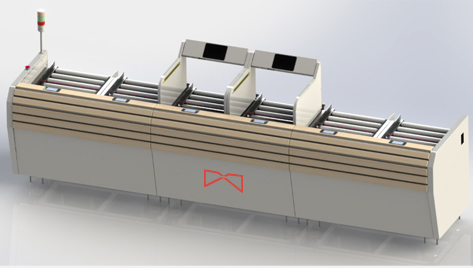

PSS105 Single-Layer Sorting Station

The PSS105 single-layer sorting station is the next-generation modular single-layer workstation developed by HWArobotics to cater for semi-automated split picking.

- Applicable Scene

-

The PSD105 modular product is an important part of the “goods-to-person” system, which is used for split picking together with the AS/RS system and the conveyor system. This PSD105 smart warehouse workstation is designed with ergonomic considerations to reduce pressure on the human body, ensuring comfortable and efficient working conditions for warehouse personnel.

Driving

Load

Overall Performance

-

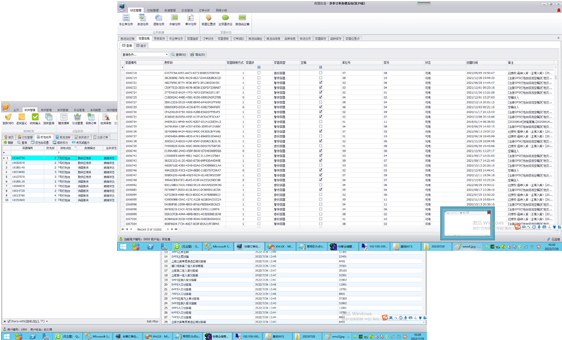

HWArobotics’ MFC SOFTWARE

MFC software is designed to streamline and monitor material flows within fully or nearly fully automated warehouses and distribution centers.

It offers a high degree of flexibility to control components such as conveyor systems, sorters, robotic solutions, shuttle systems and lifts – even from diverse manufacturers.

Visualization and route optimization techniques are used to map out all storage areas for optimal order execution.

MFCs integrate seamlessly within facility logistics processes, whether set up independently or as part of an existing WMS. The software offers complete oversight at all times to facilitate user interventions as needed.

HWArobotics’ MFC provides a high level of process data to help clients better understand their machines and systems. Advanced data visualization capabilities enable users to quickly get access to system status and throughput performance. This may include number of pallets, orders or dual cycles the system has handled within a given period.

- Applicable Scene

-

Driving

Load

Overall Performance

-

FPSS1500A | Four-directional Pallet Shuttle System For Room Temperature Environment

The FPSS1500A four-directional pallet shuttle system uses only European series parts(Core Components) and powered by 100% electricity, enhancing quality, reliability, and control ability while lowering the failure rate. It has also achieved swarm intelligence in the PSR system with AI scheduling algorithms, realizing optimum efficiency by automatically adjusting the efficiency based on the number of vehicles and the rack structure.

Suitable for case picking:

1. Use only European parts: Major devices use quality European branded components

2. All-electric drive: Only electric drive is adopted for control

3. Speedy delivery: Within 100 days after the completion of contract price payment

4. High reliability: The highest reliability standard is maintained

5. AI deployment: Swarm intelligence of the PSR system is achieved with the AI deployment algorithm. The efficiency is automatically adjusted based on the number of shuttles and the rack structure to obtain the optimal efficiency

6. Global standard certification: CE and UL certification- Applicable Scene

-

The FPSS1500 four-directional pallet shuttle system is suitable for full case picking, including tobacco raw materials and finished products, food and beverage, industrial manufacturing, and other industries.

Driving

Load

Overall Performance

-

GTR200 Goods-to-Robot Sorting Station

The GTR200 goods-to-robot sorting station is an innovative solution for optimizing the split-picking process. The robots can repeat picking actions for a long time to save stuff’s power, significantly improve picking efficiency and ensure accuracy. As the labor cost is getting higher, goods-to-robot sorters undoubtedly have their unique advantages.

- Applicable Scene

-

Powered by machine vision recognition, HWArobotics’s goods-to-robot system is the core technology for unmanned warehouse material handling. It can also be used for inspection, replenishment, palletizing, and other tasks in addition to sorting. The goods-to-robot system can unlock productivity with 24/7 uninterrupted operations.

Driving

Load

Overall Performance

+49-160-94400866