Types of Pallet Shuttle Systems: How to Choose?

In the fast-paced world of warehousing and logistics, efficiency and space optimization are important. The pallet shuttle system is one creative fix that has gained appeal. This modern technology provides an organized system for storing and retrieving, increasing efficiency and reducing operating costs.

This blog will guide you into the pallet shuttle systems world, explaining the different types and supporting you to make an optimal decision when it comes to choosing the right system for your specific needs.

(Copyright image from Freepik)

△Understanding Pallet Shuttle Systems

The pallet shuttle system is a semi-automated storage solution used to enhance the efficiency of the warehouse. It is made up of dedicated shuttle robots that move and store pallets inside a racking system. These robots work in conjunction with forklifts or stacker cranes to efficiently move pallets in and out of storage position.

The main purpose of a pallet shuttle robot is to improve space utilization and raise storage capacity. With the absence of aisles between racks, these systems use the vertical space effectively. In addition, they improved inventory control by offering real time status and accelerated picking operations of products.

▲Features and Benefits Of Pallet Shuttle Systems

Pallet shuttle systems provide a variety of features and advantages, which makes them the most popular in the industry. Some key features and benefits include:

☞High Speed and Efficiency: The shuttle robots run at high speeds, enabling fast pallet handling and reducing waiting times.

☞Reduced Labor Costs: Pallet shuttle systems eliminate the need to be manually carried out by automating the storage and retrieval process, which translates to cost savings for businesses.

☞Improved Safety: The substitution of forklifts with shuttle robots in the warehouse considerably lowers the risk of accidents and injuries.

☞Flexibility:These systems are easily adaptable to the existing structures of racking, which makes them a flexible solution for different warehouse environments.

☛Scalability:Storage systems can be scaled or adjusted to meet future storage requirements and business growth.

△What are the Different Types of Pallet Shuttle Systems?

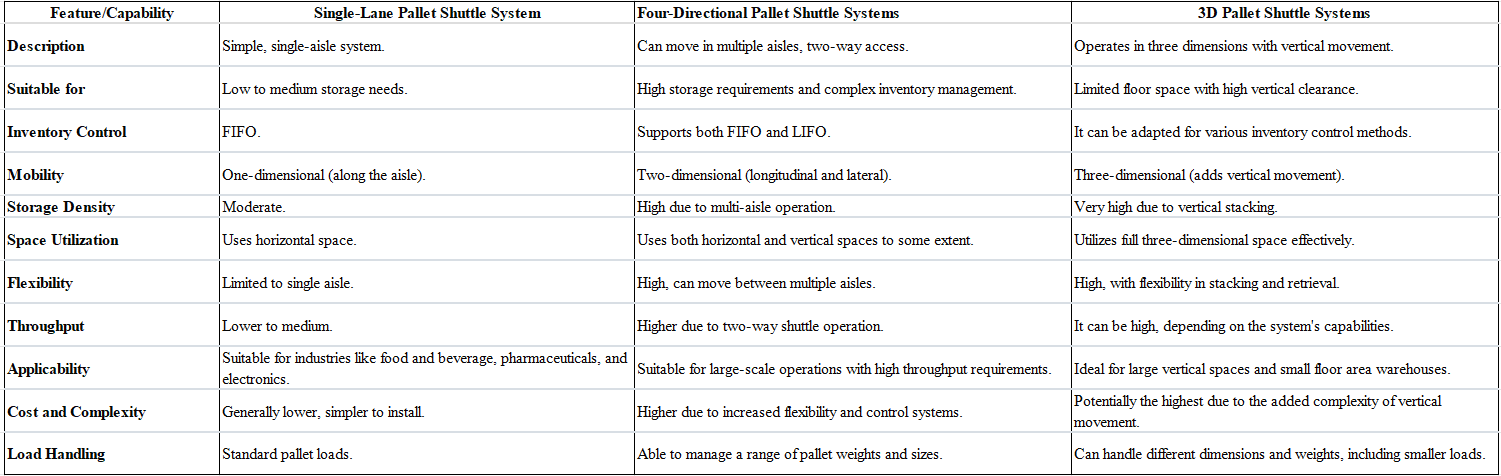

Pallet shuttle systems come from various types of working mechanisms, significant applications, advantages, and considerations. Let’s explore the three main types in detail:

△When to Choose Pallet Shuttle Systems?

There are many advantages that shuttle pallet racking systems provide, which makes them a suitable option for different warehouse environments. Let’s explore some scenarios where choosing a pallet shuttle racking system would be advantageous:

▲High-volume Storage and Retrieval

Pallet shuttles systems are especially advantageous for warehouses that handle large amounts of inventory. This system is automated; therefore, storage and retrieval are done quicker, handling time is minimized, and overall effectiveness is better.

▲High-Density Storage in a Constrained Area

When the floor space of your warehouse is constrained, the pallet shuttle systems can help in maximizing the storage capacity. These systems make use of vertical space and do away with aisles, allowing for even denser storage without impairing accessibility.

▲Cold Storage Facilities

Cold storage systems need special storage methods that can bear low temperatures. These types of systems are intended to work in these kinds of environments and, thus, are perfect for cold storage facilities.

▲Real-Time Inventory Visibility

Pallet shuttle systems offer real-time visibility so that you can track and manage your stock accurately and effectively. This functionality is extremely important for those warehouses, which work with perishable or time-sensitive goods.

△Navigating Challenges of Implementing Pallet Shuttle Systems

Pallet shuttle systems offer efficient and high-density storage solutions in warehouses, but like any technology, they come with their own set of challenges. Here are some common issues associated with pallet shuttles and strategies for navigating them.

▲Limited Pallet Weight and Size

- Select pallet shuttle systems with higher capacity:Assess the weight and size restrictions of your pallets and select a shuttle system that can handle them. If you often have to handle heavy pallet loads, consider shuttle systems with higher weight capacities.

- Optimize pallet design:You should think about refining or optimizing your pallets so that they provide the maximum utilization of space, weigh the least, and still satisfy your product storage needs. This can improve the operational effectiveness of your shuttle system.

▲Compatibility with Existing Infrastructure

- Assess existing infrastructure and modification needs:Evaluate your current warehouse layout, including rack configurations and aisle dimensions, to determine the compatibility of pallet shuttle systems. Identify any necessary modifications or adjustments required to integrate shuttle systems seamlessly.

- Integrate shuttles with traditional pallet racking systems: If you have existing pallet racking systems in place, explore options for integrating shuttle systems into your setup. This may involve retrofitting racks or implementing hybrid solutions that combine traditional racks with shuttle technology.

By addressing these challenges effectively, you can make informed decisions about when to choose pallet shuttle systems and ensure smooth implementation within your warehouse operations.

△HWArobotics: Quality Pallet Shuttle Systems and Solutions Provider

HWArobotics’ pallet robots offer an innovative solution for optimizing warehouse operations.

▲FPSS1500A: Four-Directional Pallet Shuttle System for Room Temperature Environment

The FPSS1500A is an all-electric, four-directional shuttle system that stands out for its:

- European Quality Components: Ensuring top-tier performance and reliability.

- AI-Powered Efficiency: With swarm intelligence and AI scheduling for optimal operational efficiency.

- Speedy Delivery: Commitment to delivering within 100 days post-contract.

- Global Standard Compliance: Holding CE and UL certifications for safety and quality assurance.

This system is ideal for industries such as food and beverage, tobacco, and industrial manufacturing, where case picking in room temperature conditions is prevalent.

▲FPSS1500B: Four-Directional Pallet Shuttle System for Low Temperature Environment

The FPSS1500B is tailored for cold storage environments, capable of operating seamlessly at -25°C. It offers:

- European Series Parts: Guaranteeing high-quality performance even in low temperatures.

- All-Electric Drive: For precise control and reduced environmental impact.

- Rapid Deployment: Aiming to deliver and install within 100 days to minimize downtime.

- High-Reliability Standards: Maintaining the highest standards to ensure minimal failures.

Perfect for cold chain logistics, the FPSS1500B serves food, medicine, and other cold storage businesses that require automated storage and retrieval in low-temperature settings.

HWArobotics’ FPSS1500A and FPSS1500B are designed to meet the specific needs of room temperature and cold storage environments, respectively. With their advanced features and the benefits they provide, these systems are a smart choice for businesses looking to enhance warehouse efficiency and reduce operational costs.

Learn more about HWArobotics to see how we can help you revolutionize your warehousing operations.

You may also want to read:

▷How Do Pallet Shuttle Robot Systems Improve Fresh Food Logistics Efficiency?

▷AS/RS Pallet Shuttle System for Changing Food and Beverage Logistics Needs