Buyer’s Guide: Single-Layer VS Double-Layer Sorting Station

In the modern warehousing and distribution industry, sorting stations ensure effectiveness and efficiency in fulfilling accurate orders. As a buyer, it is necessary to understand the possibilities available to make an informed decision based on your business needs. This blog will discuss the differences between single-layer and double-layer sorting stations, including their configurations, functionalities, benefits, and drawbacks. With this guide, you now have a full understanding of warehouse sorting systems, and by the end, it will be easy to choose the right solution for your warehouse.

Sorting Stations and Their Layers: A Brief Explanation

Sorting stations are special workstations that ensure the rearranging of items in a warehouse is done excellently. It is a center place where products are placed, arranged, and labeled before being taken for shipment. One of the critical considerations for choosing the kind of warehouse sortation system is the number of layers.

The layer refers to the number of levels or tiers an item can be sorted. A sorting station could be called a single-layer type if it has one level at which sorted items are disposed into fixed bins or containers automatically or manually. On the other hand, a double-layer sorting station has two levels with increased sorting capacity and flexibility.

Single-Layer VS Double-Layer Sorting Station

Single-layer warehouse sorters are often preferred in smaller warehouses or facilities with limited space. They are generally more compact and require less installation effort. The sorting process in a single-layer station is typically linear, where items move sequentially along the conveyor or chute. This simplicity makes it easier to set up and maintain.

Double-layer sorting stations, on the other hand, offer a higher sorting capacity due to their dual-tier design. They allow for parallel sorting, where items can be sorted simultaneously on both levels. This increases the overall throughput and enables more flexibility in sorting criteria. For example, one tier can be dedicated to sorting by SKU while the other tier sorts by destination. This versatility makes double-layer sorting stations ideal for larger warehouses with high order volumes and complex sorting requirements.

Respective Advantages and Disadvantages

There are different factors of warehouse operation that influence the choice between single-layer and double-layer sorting stations. Single-layer sorting stations are easy to use and less expensive; hence, their use in smaller operations has less complex requirements. They also easily link up with the current systems and require minimal maintenance. However, sorting capacities may be limited, which may not be ideal in warehouses where the picking volumes are growing rapidly.

On the other hand, double layers of sorting stations present a higher level of throughput and flexibility for sorting. These are appropriate for warehouses with high order volumes requiring various sorts. Their installation and maintenance are harder and more costly than single-layer stations. Additionally, the increased complexity may require additional training for operators to ensure efficient and accurate sorting.

Overall Buying Guidance: Factors to Consider

Several factors come to the fore when choosing between single-layer and double-layer warehouse sorting stations:

✔Sorting Volume: Consider the average daily number of sorting in your warehouse and whether a single-layer or double-layer station will suffice.

✔Available Space: Assess the available space in your warehouse and determine a sorting station that will fit accordingly without interference from any other operations.

✔Automation Needs: Consider the level of automation required for your sorting processes. If speed and efficiency are crucial, a double-layer station with advanced automation capabilities may be the best choice.

✔Budget: Establish your budget and consider the cost-benefit of single-layer and double-layer stations, including factoring in long-term costs for maintenance and repair.

✔Customization: Let your sorting processes dictate the need for customization. A single-layer station may be flexible enough if your warehouse deals with unique or specialist items.

With careful consideration of these factors, buyers can make informed decisions on particular warehouse needs.

HWArobotics: Recommended Sorting Stations

For buyers seeking reliable and efficient sorting stations, HWArobotics offers two exceptional options: the PSD310 Double-Layer Sorting Station and the PSS105 Single-Layer Sorting Station.

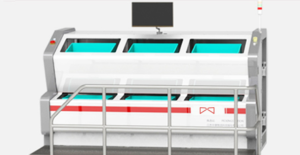

The PSD310 Double-Layer Sorting Station provides unmatched sorting capacity and flexibility. Its dual-tier design enables parallel sorting, increasing productivity and optimizing workflow. The station integrates seamlessly with various warehouse management systems and automation technologies, ensuring smooth operations. Its robust construction and advanced sorting algorithms guarantee accurate and efficient sorting, even in high-demand environments.

PSS105 is your next-gen solution for semi-automated split picking. It implies a compact and cost-effective solution for this capability’s implementation in smaller warehouses. It guarantees reliable performance in sorting yet demands minimum effort for the purpose of its installation and maintenance. Its durability and compatibility with various sorting criteria make it a reliable choice for warehouses dealing in moderate order volumes.

HWArobotics, headquartered in Singapore, specializes in developing and supplying top-tier warehouse and logistics robot solutions worldwide. Our extensive product line includes the pallet shuttle system, tote shuttle system, mini shuttle system, split case picking system, and accompanying control software, all designed to meet the highest quality standards.

Enhance productivity, accuracy, and employee well-being with HWArobotics’ workstations. Revolutionize your warehouse experience – invest in innovation. Upgrade your operations today!

Conclusion: Discover HWArobotics and its Product Range

Sort stations are a critical feature of modern warehousing and distribution operations. By learning the differences existing between single-layer and double-layer sorting stations, consumers can make informed and wise decisions relating to their particular needs. HWArobotics stands out as a trusted provider of innovative sorting solutions. Our PSD310 Double-Layer Sorting Station and PSS105 Single-Layer Sorting Station offer exceptional performance, reliability, and customization options. Whether you require high-speed automation or flexible manual sorting, HWArobotics has the perfect solution for your warehouse.

Visit our website today and discover all that HWArobotics has to offer. Start revolutionizing your warehousing operations!