Automated and Semi-Automated AS/RS Robotics Solutions: Which to Choose?

In the fast-paced logistics world, warehousing solutions are crucial in efficient supply chains. The choice between automated and semi-automated AS/RS robotics is pivotal for the future of warehouses. This article delves into these options, examining their features, benefits, and applications. We will explore the distinctions and advantages of both AS/RS robotics solutions to help make an informed choice.

▲The Evolution of Warehousing Solution with AS/RS Technology▲

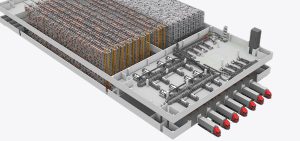

Innovations like AS/RS robotics technology and storage systems have transformed warehouse operations, boosting efficiency, reducing errors, and optimizing space. AS/RS systems, combined with efficient robots, offer flexibility and scalability for warehouses. This adaptability caters to businesses dealing with diverse products. AS/RS technology and robotics are now crucial in modern warehousing and supply chain strategies, providing significant value through increased productivity, accuracy, and scalability.

▲Automated Warehousing Picking Systems▲

Automated warehousing picking systems are the core of modern warehousing, employing conveyors, robots, and software to automate order fulfillment. They eliminate the need for manual item retrieval and transport, significantly boosting efficiency. Integration with inventory software ensures real-time tracking, minimizing errors and stockouts.

1. Key Features of Automated AS/RS Robot Picking System

√ High-Level Automation: These systems are fully automated, utilizing robotics, conveyors, and advanced machinery to handle various tasks without human intervention.

√ 24/7 Operation: They can operate around the clock, increasing productivity and reducing processing times.

√ Inventory Tracking: Real-time tracking and data collection provide insights into inventory levels, movement, and order status, improving decision-making.

2. Benefits of Automated AS/RS Robot in Warehousing

√ Efficiency and Speed: Automated robot systems can significantly enhance warehousing efficiency by reducing manual labor requirements. This results in faster order processing, reduced errors, and improved throughput and potential revenue.

√ Accuracy:Automated systems minimize human error, leading to a decrease in mis-picks and returns.

√ Cost-savings:While there’s an initial investment, automation can lead to significant long-term labor cost reductions.

√ Space Optimization:Automated racking and shelving solutions can store more items per square foot than traditional methods.

√ Safety:Robots can handle heavy or low-temeperature items, reducing workplace injuries.

▲Semi-Automated Warehousing Systems▲

A semi-automated warehousing robot system is a hybrid approach that combines human involvement with automated technology. Tasks like picking, sorting, and placing involve machines like guided vehicles or robotic aids but still rely on human input for decision-making and complex tasks, often incorporating automated conveyors or sorters alongside manual control.

1. Key Features of Semi-automated AS/RS Robot Picking System

√ Human-Machine Collaboration:These systems involve the cooperation of human operators alongside automated equipment, such as robots or conveyors.

√ Flexibility:Semi-automated warehouses can be adapted easily to handle various products or order sizes, making them suitable for industries with diverse inventory.

√ Customization:They can be tailored to meet specific warehouse needs, ensuring efficient workflows and inventory management.

2. Benefits of Semi-automated AS/RS Robot in Warehousing

√ Effective: Semi-automated systems are often more cost-effective to implement and maintain than fully automated systems. They balance automation and manual labor, resulting in lower initial investment and operating costs.

√ Scalability: Semi-automated systems are usually more scalable and operational. Warehouses can add automation components on an as-needed basis, making it easier to adapt to business growth or changes in demand.

√ Risk management:Semi-automated AS/RS robots contribute to risk management. With manual involvement, workers can respond quickly to unforeseen situations, reducing the risk of operational disruption.

▲Applications Of Automated & Semi-Automated AS/RS Robotics Solutions▲

√ Semi-Automated AS/RS Robot Shuttle System:These systems blend human skill with robotic precision, which are widely adopted in e-commerce, automotive, and food industries. They offer flexibility and adaptability to handle diverse products.

√Fully Automated AS/RS Robot Shuttle System:Ideal for industries where speed and precision are vital, such as pharmaceuticals, fashion, electronics, and food sectors. They ensure uncompetitable quality, quick operations, and minimal waste.

▲HWArobotics – Your Gateway to Advanced Warehousing Solutions▲

HWArobotics, headquartered in Singapore, is committed to delivering top-notch warehousing and logistics robotic solutions worldwide. Our product range encompasses pallet shuttle systems and associated control software. With more than two decades of expertise and cutting-edge technology, we’ve engineered highly advanced, dependable, and stable products.

Our automated and semi-automated AS/RS robotics solutions stand out as some of today’s most promising offerings in the market.